Single Cell Isolation Methods for Cell Line Development

Superior Cell Cloning Efficiency, Better Scalability

- Traditional Single Cell Isolation Methods for Cell Line Development

- Single Cell Isolation Workflow using Bio-Techne's Single Cell Dispensers

- Benefits of Bio-Techne's Single Cell Sorters in Cell Line Development

- Resources for Cell Line Development

- Testimonials From Your Peers

Traditional Single Cell Isolation Techniques for Cell Line Development

Chinese hamster ovary (CHO) cells are widely used in therapeutic antibody production. Generating a clonal cell population is key to making stable cell lines for therapeutic antibody production. A typical cell line development workflow begins with transfection of CHO cells with an immunoglobulin (IgG)-expressing vector of choice. Single, viable CHO cells that have been transfected are then isolated for clonal expansion; high titer clones are screened for stability and productivity. The next step is to expand these high antibody-producing CHO cell lines for large scale antibody production.

A critical step in the cell line development workflow involves the isolation of single, viable cells. Fluorescence-Activated Cell Sorting (FACS) or limiting dilution have traditionally been used to achieve single cell clones although each method has inherent drawbacks. FACS instruments require specialized training, have significant set-up time, and, crucially, require replacement of fluidics lines to ensure no sample-sample cross-contamination occurs. Additionally, FACS utilizes high pressure (up to 70 PSI) which can induce stress and reduce cell viability, especially for difficult to express proteins.

While gentler than FACS sorting, limiting dilution is labor intensive, time consuming, and inefficiently produces single cell clones. These drawbacks highlight the need for more automated, high-throughput solutions.

Bio-Techne's single cell dispensers offer an automated, high-throughput alternative to traditional single cell isolation methods such as FACS sorting.

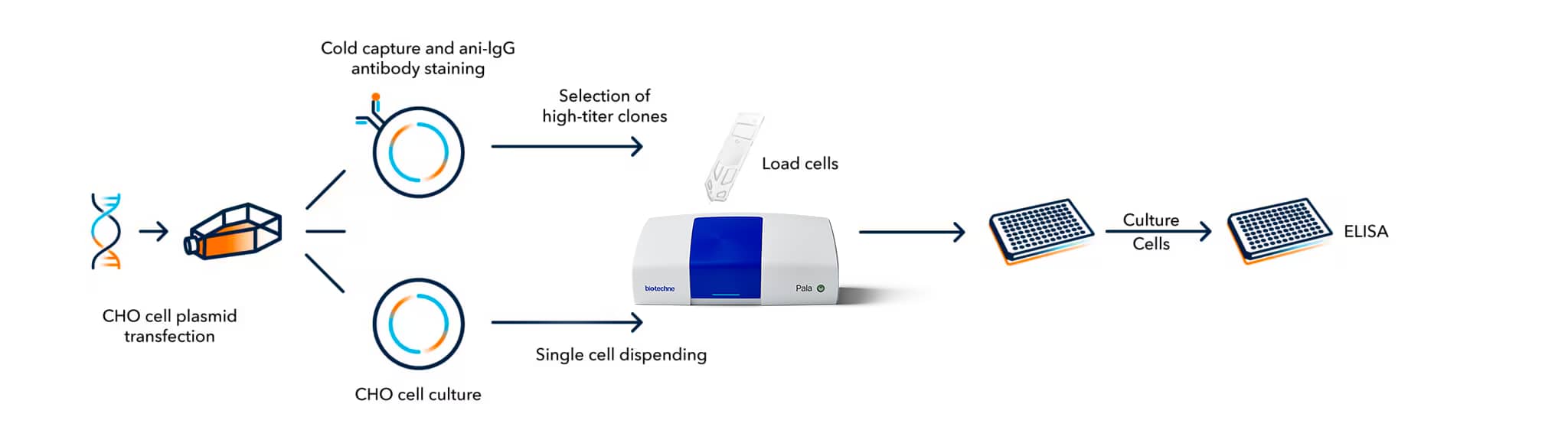

When using a Bio-Techne single cell dispenser in your cell line development workflow, CHO cells are transfected with a plasmid, encoding the desired protein for mass production, as for traditional methods. Following transfection, however, cells in suspension are loaded into a proprietary microfluidic single cell or bulk sorting cartridge and dispensed into 96- or 384-well plates using our Pala Single and Bulk Cell Sorter. A single cell cloning protocol is then used to generate cell colonies, and the resulting colonies can be analyzed via ELISA to determine antibody titer.

The rapid and gentle single cell isolation offered by our benchtop instruments can help to preserve cell integrity and viability.

Fast Cell Isolation and Single Cell Dispensing

Empower your cell line development workflow with the fastest and simplest way to identify and isolate single cells in as little as 7 minutes from instrument start-up!

Efficient Single Cell Sorting

Proprietary benchtop sorting technology is affordable, user-friendly, and requires minimal training.

Gentle Cell Sorting and Dispensing

Cell samples are sorted and dispensed under gentle conditions (<2 PSI) helping to preserve viability and integrity throughout the cell line development workflow.

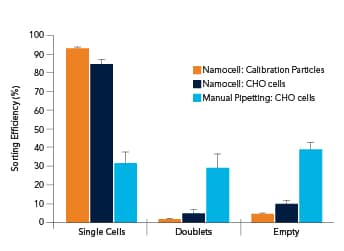

The figure (right) shows that Bio-Techne instruments are highly efficient and consistent at dispensing single cells (80-90% with mammalian cells) compared to manual pipetting (~30%).

Single Cell Cloning Efficiency

The figure shows a comparison of Bio-Techne’s Single Cell Dispenser with traditional methods of sorting cells for clonal outgrowth. Bio-Techne’s Single Cell Dispenser, was used alongside limiting dilution (LDC) and FACS sorting to sort CHO host cells for a single cell cloning protocol sorting. Results highlight the higher cloning efficiencies obtained with Bio-Techne’s platform compared with LDC and FACS.

Resources

Cold-Capture Single Cell Isolation for CHO Cell Line Development

Results from Namocell single cell dispensers showed a 3x increase in IgG production from cold-captured cells compared to non-captured cells.

CRISPR-Edited Cell Line Development Workflow Improvements

Dr. Oscar Perez-Leal of Temple University explains how obtaining a pure clonal population of CRISPR-edited cells is critical yet challenging, and how the Namocell Single Cell Dispenser was instrumental in streamlining and accelerating the development of cell line models.

Single Cell Dispensing Efficiency

Learn how Bio-Techne’s single cell dispensers provide a fast and reliable alternative for single cell isolation with increased accuracy in dispensing single cells.

Dr Oscar Perez-Leal, MD, Assistant Professor, Temple University, School of Pharmacy

“Utilizing this machine [the Bio-Techne Single Cell Dispenser] has proven instrumental in streamlining the development process of single-cell clones for the cell lines I am working on. It has greatly facilitated the generation of valuable research tools, contributing to the overall progress and efficiency of my work.”

Dr Lina Chakrabarti, Associate Director R&D, AstraZeneca

“The introduction of [Bio-Techne] Single Cell Dispenser has brought significant reduction in sorting time and cost of goods. The device is small, quick to set up and easy-to-use with high probability of monoclonality and clonal outgrowth.”