The promise of immune cell therapies is being limited by a significant obstacle - ensuring these highly sensitive, biological products can be manufactured consistently and reliably.

Patient safety must come first. Always.

As such, regulatory agencies have made reproducibility a top priority, where process development and product understanding are vital in ensuring a consistent manufacturing process. Developers must demonstrate robust quality control and stringent analytical testing to thoroughly characterize products and validate manufacturing processes. Failure to meet these standards has already setback several prominent BLA approvals.

The very nature of immune cell therapies brings an inherent variability that must be carefully controlled. Factors like donor variability, raw materials, cell handling and manipulations can also impact the final product. As a result, rigorous strategies to reduce variability and control quality at each stage are crucial to ensure safety and efficacy and, ultimately, commercialize your cell or gene therapy.

4 Steps to Scalable Immune Cell Therapy Production

So how can we overcome these roadblocks to scalable, consistent immune cell therapy manufacturing? The strategies are multifaceted but achievable with the right expertise and tools. Here are four elements in the roadmap to consistency and reproducibility:

1. Standardizing Processes and Raw Materials

Establishing standardized protocols from cell sourcing through bioprocessing lays the groundwork for consistency. Optimizing each unit process from cell isolation, expansion, genetic modification, to downstream processing with validated technologies is fundamental.

Raw materials bring another layer of variability and can have a huge impact on the consistency of your final product, and so sourcing the right materials from reliable suppliers minimizes this variability upstream. Lot-to-lot consistency and supply chain robustness should be part of any due diligence when selecting raw materials suppliers, as well as their ability to supply GMP-grade materials for that all-important transition into clinical development.

2. Defining Critical Quality Attributes

Consistent product quality is attained by identifying and measuring the right critical quality attributes (CQAs) to fully characterize your product. These CQAs need to be mechanistically relevant, i.e. you must be able to demonstrate your product’s mechanism of action to get regulatory approval, rather than simply measuring generic quality attributes. This has proved challenging given the complexity of immune cell biology and function. Potency is proving to be the most complex CQA, leading the FDA to publish draft guidance on “Potency assurance for Cellular and Gene Therapy (CGT) Products” at the end of 2023.

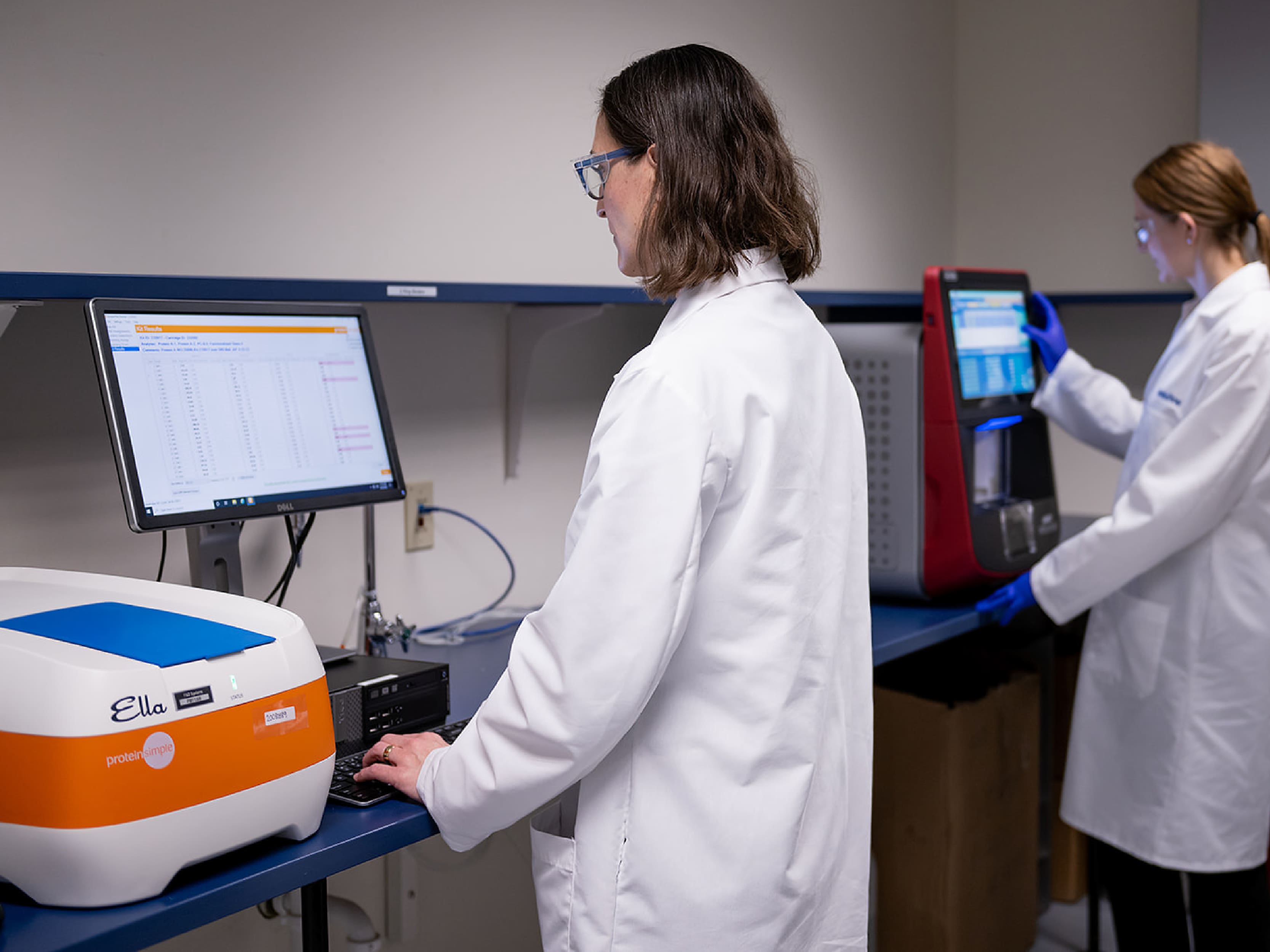

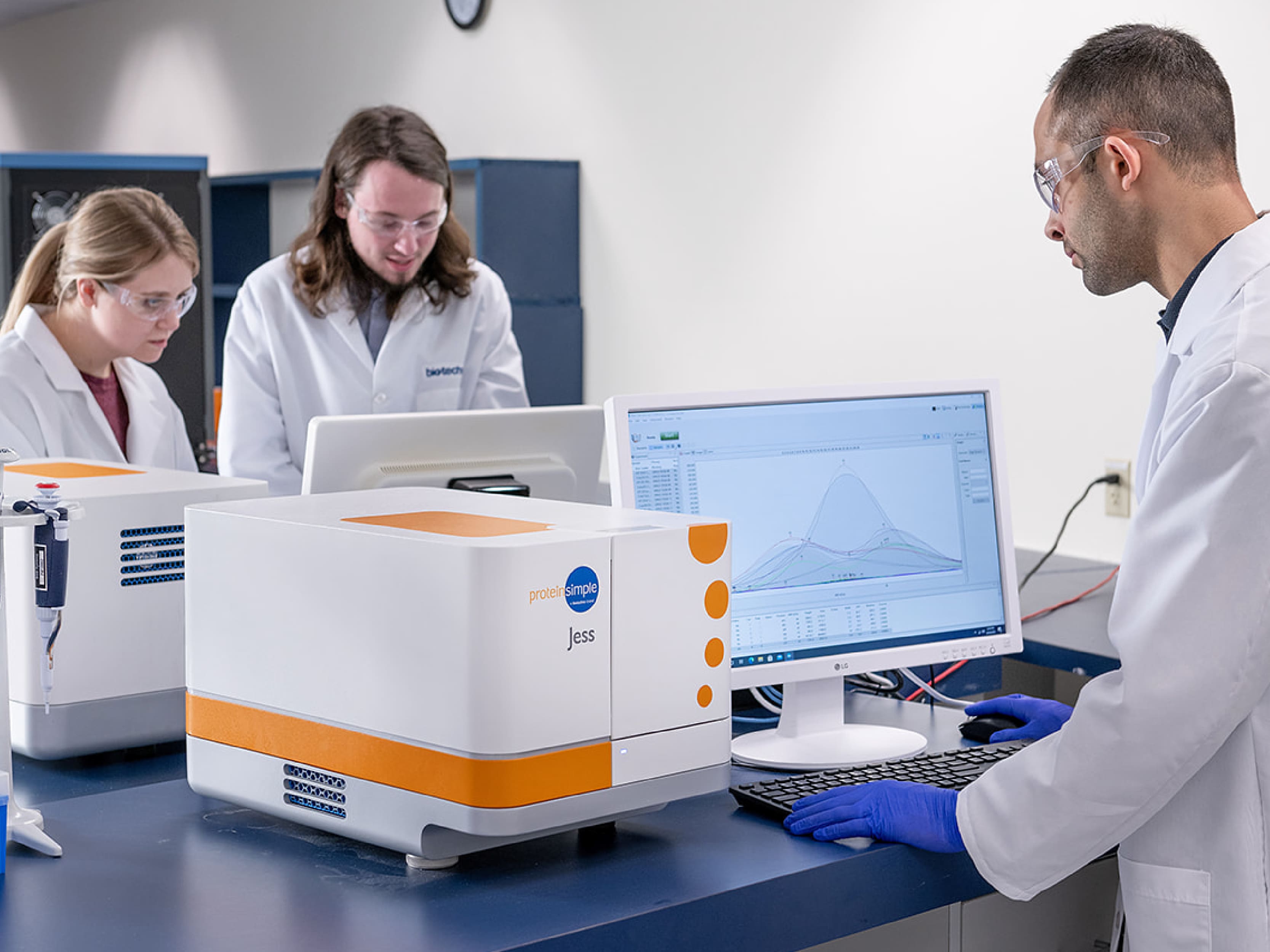

A matrix of validated analytical methods provides a multi-dimensional view into identity, purity, viability, potency, and other critical parameters. As clinical development progresses, testing can be refined to focus on the most predictive or relevant attributes. Once your CQAs are defined, vigilant quality control with regular testing at all manufacturing stages is vital.

3. Process Development and Validation

In addition to CQAs, critical process parameters (CPPs) are required to validate your process and achieve consistent production. FDA defines CPPs in section IV A of the aforementioned draft guidance:

“CPPs are manufacturing process parameters that can influence CQAs. You should identify CPPs that may affect potency related CQAs, and you should monitor or control these CPPs within appropriate pre-determined limits.”

Evaluating multiple production batches under various conditions will allow you to identify your CPPs and acceptable operating ranges. CPPs and CQAs must be maintained throughout your process and, together, these systematic validation studies provide evidence of manufacturing robustness and reliability.

Validation studies will likely require in-process testing to demonstrate consistency of your product from batch to batch. This investment is essential for ensuring lot-to-lot consistency, preventing costly manufacturing disruptions, and securing regulatory approvals.

4. Partnering for Success

No developer can overcome the burden of reproducibility and consistency alone. Collaborating with specialized suppliers and partners provides access to high-quality materials, cutting-edge analytical technologies, plus regulatory and manufacturing expertise. This allows you to streamline and focus resources on progressing transformative therapies reliably and rapidly to patients in need.

Roadblocks around manufacturing consistency have stalled too many breakthrough therapies. Conquering these hurdles through strategic standardization, rigorous quality testing, comprehensive validation, and strong partnerships will unlock the full potential of immune cell therapy. Prioritizing reproducibility accelerates development timelines and ensures patient safety.