Meeting the Challenges of Scale: Designing the Cell and Gene Therapies of the Future

To facilitate communication and collaboration across the cell and gene therapy (CGT) field, Bio-Techne hosted the first CPD-certified Cell & Gene Therapy Symposium on the 7th November 2019 at the QEII Centre in central London. With an overarching topic of ‘Meeting the Challenges of Scale: Designing the Cell & Gene Therapies of the Future’ the one-day forum aimed to provide a much-needed platform to discuss the key topics and challenges faced and important solutions for these—as the manufacturing of advanced therapy medicinal products (ATMPs) at scale becomes a reality.

What did we learn at the first CPD-certified Cell and Gene Therapy Symposium?

|

|

The field is rapidly accelerating with over 1,000 CGT companies in operation today and, as highlighted in the Alliance for Regenerative Medicine “Trends in ATMP Development” 2019 report, over 1,000 ATMP clinical trials in progress worldwide. A vast array of new cell types is entering the clinic with the promise to revolutionize the treatment of a wide range of conditions. However, alongside this exciting progression comes the many challenges of GMP scale up and scale out that are exposing bottlenecks and creating obstacles that hamper the arrival of treatments into the clinic.

With the aim of tackling these issues head-on, the Bio-Techne forum brought together 51 of the world’s leading CGT experts in a day that was structured to ‘Set the Scene’, ‘Look at the future and new cell types entering the clinic’ and ‘Think about solutions’ in three engaging sessions. In addition, there were interactive audience polls, a thought-provoking panel discussion, Q&A sessions and a plethora of networking opportunities throughout the day.

Delegates viewed the day with great positivity—as a valuable and much-needed opportunity to come together to debate and collaborate on key issues. The event was rated 4.8 out of 5 with all respondees agreeing that the objective of discussing the challenges of scale had been met.

The key message of the day was the need for industry collaboration to tackle the challenges faced in this rapidly progressing field as therapeutics transition to the clinic.

With so many CGT companies producing therapeutics for clinical trial, the symposium highlighted that for the promise of these to be fully realized, the challenge of scale across the entire supply chain must be addressed.

Bio-Techne is committed to facilitating this and will continue to ask the CGT industry what is needed and wanted in order to achieve it. As part of this, the company has announced the Second European Cell and Gene Therapy Symposium to be held in Amsterdam 2020 - creating an even larger forum to support the CGT field and work together to meet and exceed the challenges of scale. To be part of this event, watch this on-demand webinar.

Setting The Scene & Today's Hurdles

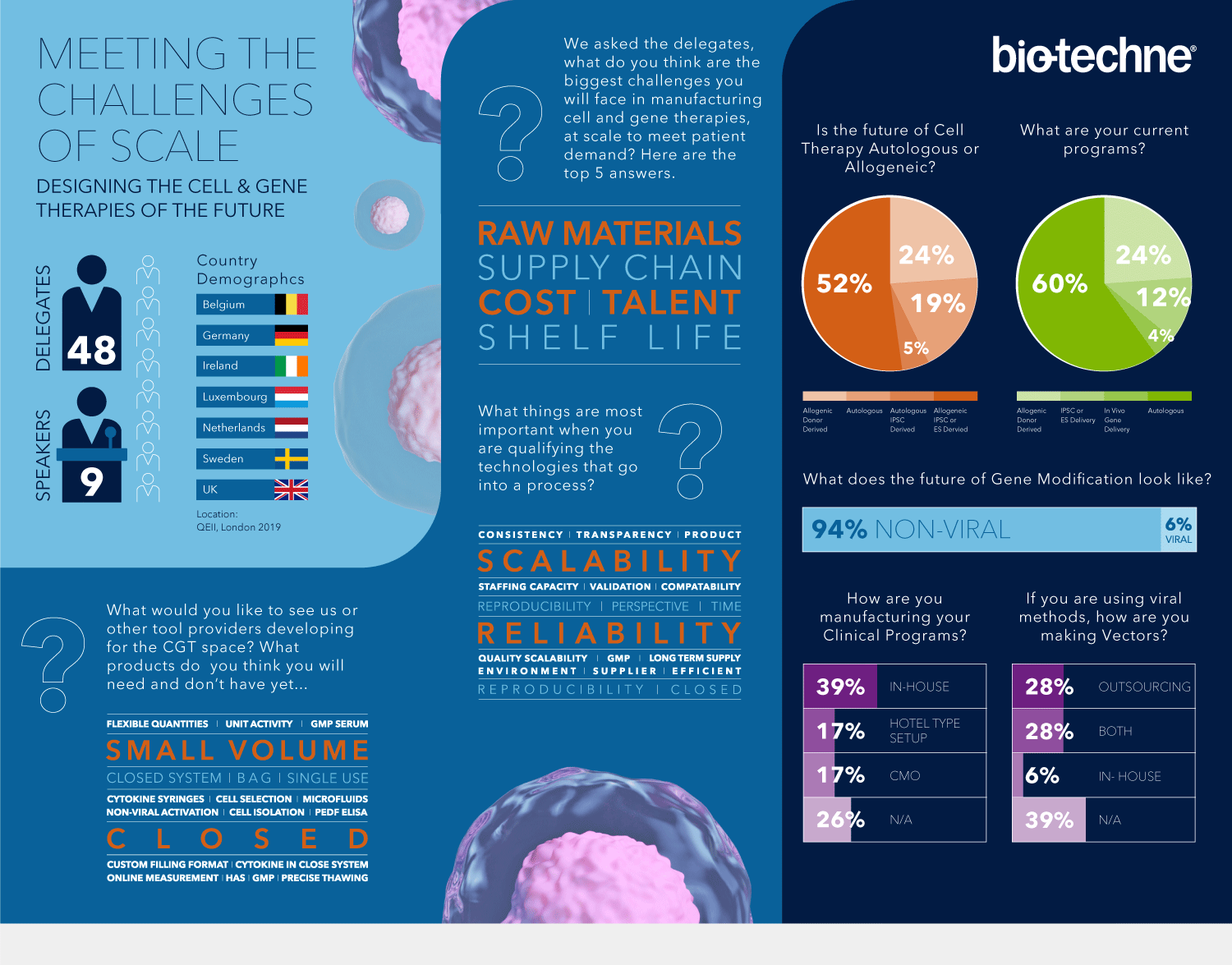

Session one kicked off with a live poll that asked delegates ‘What do you think are the biggest challenges you will face in manufacturing your cell and gene therapies at the scale needed to meet patient demand?’

The responses clearly highlighted key issues around scalability with GMP raw materials and the supply chain sharply in focus, as well as personnel expertise, cost, product cryopreservation, QC and product shelf life.

It is essential to challenge the status quo within the CGT field, and that “disruption is needed in the industry to drive change”.

The panel went on to discuss the changing structure and timelines of clinical trials and highlighted the pressure placed on ATMP manufacturing and supply at scale. He argued that there are three key industry barriers; making the clinical framework work at scale, the challenges of health economics, GMP manufacturing and supply chain, all clearly underpinned by a need for talent and skills. A valuable tool to address these bottlenecks are scalable test beds, especially where processes are still slow and lack integration.

Talks from Professor John Campbell, Scottish National Blood Transfusion Service, and Dr. Jef Pinxteren, Promethera Biosciences shared valuable lessons from cell therapy development programs, both showcasing the importance and benefits of using Xeno-free media throughout the entire ATMP development process—not just at GMP—to enhance results and ensure a smoother transition to GMP scale-up. Professor Campbell also identified liquid waste handling as a key practical problem at large volume that is easy to forget until you are in the clean room at scale. A key message from his presentation was to ‘start with GMP manufacturing in mind’ and that doing so ensures a faster scale up.

Dr Darrell Sleep, Director of Innovation, Cobra Biologics highlighted scale up considerations for viral vector manufacturing, noting that the move to GMP is associated with high risk, particularly where “the raw material supply chain can be an intricate web, especially when you consider vector design”.

Not all vectors are the same and many factors can affect both yield and recovery, something which is compounded by the absence of standard platforms across the field.

Session two emphasized the many new cell types entering the clinic. Dr Heather Main from the Karolinska Institute highlighted that pluripotent stem cells necessitate many raw materials and typically require over 60 independent raw materials per product. With the use of so many material components, there needs to be a seamless transition between the raw material acquisition and the GMP-manufacturing teams producing the ATMP.

Volker Huppert, Glycostem Therapeutics discussed natural killer cell therapies emphasizing the need for fully closed manufacturing system—a recurring theme throughout the day—and a lack of GMP-qualified operators that cause manufacturing bottlenecks.

Automation and Quality Control (QC) underinvestment were also keenly debated in this session, as was the need for trusted supply agreements with reputable companies.

Louisa Mathias, GammaDelta Therapeutics argued that it is essential to “select quality materials from established suppliers to transition to GMP”, while Pernille Linnert Jensen, Novo Nordisk advised “collaborating with raw material suppliers and looking at the long-term scope”.

Thinking About Solutions

Session three sought to answer the call for CGT solutions raised in the previous sessions. Delegates were asked what tools they would like to see developed and the room clearly called for closed systems and flexible volumes.

Jenny Stjernberg, Bio-Techne, exemplified the pre-requisite GMP perspective discussed in the previous sessions, presenting a large portfolio of GMP-proteins and GMP-reagents supported by comprehensive experience in reagent optimization and GMP-scale up.

The need for robust supply agreements for all the raw materials alongside supplier redundancy was acknowledged and welcomed, while immunoassay and proteomic platforms to deliver QC automation were exhibited.

To tackle problems of starting material, Dr Diana Hernandez presented Anthony Nolan’s new offering of human cell material for the CGT industry including a public cord blood bank and adult material from its vast volunteer donor register. Dr Hernandez highlighted the inherent complications with the shipment and sourcing of cell products to ensure high quality, traceability and regulatory compliance.

Regulatory paperwork can produce an enormous bottleneck in GMP manufacturing, and Professor Mark Lowdell, Autolomous, presented an innovative digital approach to solve this – electronic batch manufacturing records.

A key message here was data security - “for digitization in ATMP manufacture, the data and storage of this data must be secure”. Digitization offers a solution to the current paperwork nightmare faced by the CGT field, especially during scale up and manufacture, ensuring that the challenge of scale can be met head on.

Looking To The Future

The panel discussion featuring Mark Lowdell, Autolomous, Stuart Curbishley, University of Birmingham, Jef Pinxteren, Promethera, Jeff Liter, Bio-Techne and Jason Jones, Ori Bio-Tech debated the future of the CGT field, particularly the question of autologous or allogenic treatments, remarking that both approaches have their place within the field, with the patient always being at the forefront irrespective of the treatment’s origin. It was argued that automation solutions while welcome, are only as good as the company who supply them and it was clear that CGT leaders want closed systems with small equipment foot-prints.

Supplier confidence, agreements and redundancy were passionately discussed where “There needs to be a relationship that will grow over time including material for supply agreements”.

To emphasize this, examples where a CGT product required a specific raw material from a single supplier were cited. This becoming unavailable had a catastrophic impact for the product.

The symposium was brought to a close with a reflection on the day and key themes by Dr Lindsey Clarke, Bio-Techne. She discussed the staggering pace at which the field has progressed in a small space of time and the need for forums such as these to serve as a ‘meeting of minds’ to collaborate and work together to meet the challenges of scale.