Services Offered

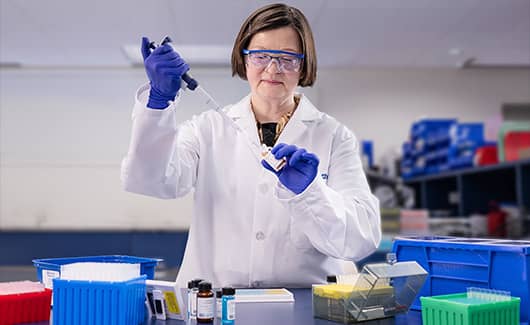

FDA-compliant and platform agnostic phase-based Design Control processes are utilized for product development of diagnostic assays (reagents, calibrators, controls, calibration verifiers, and proficiency testing materials) from research and development to product transfer.

- IVD Assay Development

- Technology Transfers

- Packaging Development

- Stability Testing

- Regulatory Support

- Technical Support

- Custom QC Testing

Benefits of Outsourcing IVD Assay Development

✓ Access Bio-Techne’s product library & expertise

✓ Increase speed to market

✓ Manage Budget & Capital

✓ Free up internal resources

✓ Dependable Manufacturing and Supply

IVD Assay Development Phases

- Assay development projects start with research and planning, along with customer meetings to define product requirements.

- Thorough research is performed on the target to understand its chemical and biological properties, its binding partners, and isoforms, to assess specificity

- Research into applicable predicate assays

- Investigation into reagents: candidate antibodies, proteins, enzymes, etc. and their availability are determined

- Dedicated program manager is assigned to the project

- Much of the assay optimization occurs in this phase. Reagents are assessed to determine the best combination to meet the product requirements determined in Phase 0

- Assay is designed to meet CLSI guidelines

- If applicable onboarding and training to a new platform is the first step in this phase

- Project updates shared regularly (weekly --> monthly)

- The optimal reagents are evaluated for assay specificity, quantification ranges (LOB, LOD, LOQ), sample performance, and initial stability

- Pilot lots of reagents are examined to verify assay performance before entry into Phase 3

- Incorporated minor changes identified in Phase 1 testing to improve robustness

- 2 reagent lots produced with varying biologically derived components

- In Phase 3 all required testing determined in Phase 0 is performed

- The 3 lots of reagents with varied biologically derived components

- Performance testing against CLSI guidelines is performed

- Calibrators and controls are produced with traceable material.

- Regulatory dossier is provided to support customer quality and regulatory requirements

- Stability studies initiated

- Transfer of the assay from the development team to Operations, QC and QA

- Scale-up to achieve commercial volumes

- If applicable, kitting is performed

- Establish supply agreement that meets commercial needs

- Implement logistics plan to distribute bulk materials or finished kits to customer sites

Technology Deployed:

Technology Deployed:

- Chemiluminescence

- Homogeneous Immunoassay

- Clinical Chemistry

- Lateral Flow

- ELISA

Recent Development Projects:

Recent Development Projects:

- Neuro/Alzheimer's markers

- Regenerative Medicine

- Toxicology:

- Therapeutic Drug Monitoring (TDM)

- Drugs of Abuse

- Cell & Gene Therapy

Our Commitment to Quality

Our Commitment to Quality

- ISO 13485:2016

- Health Canada

- FDA 21 CFR Part 820

- MDSAP

- ISO 14001

- US DEA

- ISO 9001:2015

- USDA

- IVDD (IVDR in process)

Additional IVD Capabilities

Custom Controls & Calibrators

Custom Controls & Calibrators

- Hematology/Flow Cytometry

- Cardiac Markers

- Serum Proteins

- Urinalysis & Urine Chemistry

- Blood Gas/Electrolytes

- CO-Oximetry

-

Glucose/Diabetes

IVD Contract Manufacturing

IVD Contract Manufacturing

- Custom Controls & Calibrators

- Assay Development

- IVD Manufacturing

- Technology Transfer

- Packaging Development

- Regulatory Support

IVD Raw Materials

IVD Raw Materials

- Cancer

- Cardiovascular

- Drugs

- Endocrine/Thyroid

- Serum Proteins

- Infectious Disease

- Steroids

- reKom Biotech